The Prestige of Garbellotto Casks

Choice Oak:

Garbellotto casks and barrels are produced from an oak mix of Quercus Robur-Pedunculata and Quercus Petrea-Sessilis species of wood. Together, this mix creates the strength Garbellotto casks are known for.

an oak mix of Quercus Robur-Pedunculata and Quercus Petrea-Sessilis species of wood. Together, this mix creates the strength Garbellotto casks are known for.

Traditional Production:

Garbellotto casks and barrels have been made in the same traditional method over the past 245 years. By keeping the technique of using direct fire to shape the staves, Garbellotto casks keep the full depth of their staves throughout the shaping process. Only after assembly does the toasting process begin as indicated by the customer.

In the final stages of production, the staves are softly planed and given a light coat of breathable, anti-mold paint to preserve and protect the cask from bacteria and outside elements.

Unique Innovation:

The double concaved arching heads, symbolic of Garbellotto's products, keep the cask strong under internal pressures and eliminate the use of unsightly transversal wooden bars at the head.

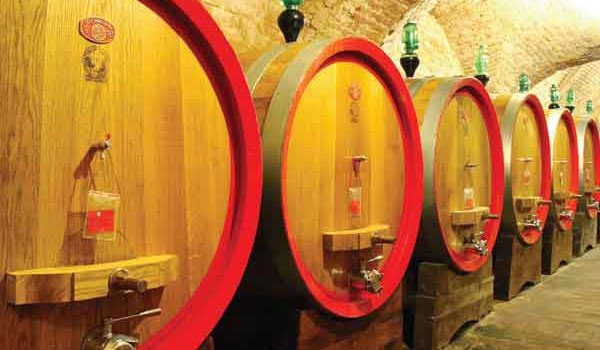

The prestige, tradition and craftsmanship that goes into each cask and barrel leaving Garbellotto makes any cellar stand out in both beauty and taste.

Garbellotto Oval Oak Casks

Accessories Include:

- Wooden manhole door in the frontal head with stainless steel AISI 304 screws and a reinforced brass nut with wooden transversal piece

- AISI 304 stainless steel ball valve mounted in the manhole door with your choice of 40, 50 or 60 mm in diameter

- AISI 304 stainless steel sample valve mounted at the center of the cask's forehead

- Bung hole plug made of soft wood or silicone

- Two wooden cask supports fitted with breathable wooden slats

- Natural, breathable, transparent, anti-mold paint applied to the outside of the cask

- Red stripe added to the staves head for easier cleaning. Added upon request

- Galvanized iron hoops. Can be colored black upon request

- Glass airlock ported through the bung hole, located at the top of the cask

Optional Accessories:

- Silicon gasket for included wooden door

|

| Optional Custom Engraving Available |

|

| |

- AISI 304 stainless steel manhole door installed in the frontal head, 240 mm x 460 mm

- AISI 304 stainless steel discharge pipe complete with ball valve and cap, installed through the bung hole, located at the bottom of the cask

- AISI stainless steel vent complete with overpressure valve, installed through the bung hole, located at the top of the cast

- Stainless steel cask stand to rotate the cask during fermentation

For special needs we can also supply the casks with other special accessories.

Optional Accessories

STAINLESS STEEL DOOR 18/8 AISI 304

Size 24 x 46 cm, easy to reach, complete with the valve requested. Fitted perfectly into one special central stave at the bottom end of the cask.

Wooden Door with Silicone Gasket

Fitted in a special central stave complete with stainless steel screw with a reinforced brass nut and a wooden transversal piece and a silicon gasket.

Total Drainage Group

Complete drainage piping assembliy in 304 Stainless Steel with Tri-Clover ball valve as requested, fitted to one central stave at the bottom of the cask.

Temperature Control

Made of stainless steel 18/10 AISI 316 plates with double welding system and probe shaft. It can be fitted horizontally or vertically depending on the height of the vat. One plate for every 50 hl holding capacity.

Upper Closing Door with Tank Vent

304 Stainless Steel Door 16-22 cm diameter, 9 cm high, complete with Pressure Relief Valve also in 304 Stainless Steel

Patented NIR® only from Garbellotto!

The only barrels with flavor guaranteed (patented)

The growth of wood, like grapes and all natural products, depends on micro climatic variables such as the degree of humidity in the area, the composition of the earth as well as the exposure of the hill or plain. The selection criteria generally used are based only on the region and the experience of the producer. It cannot be said that wood originating from a specific region has a higher level of polyphenols than others grown in other regions, since the origins don’t make the difference, whereas the single stave does. If we think about the difference between the grapes produced in one vineyard and others produced at a distance of 5 km we can well understand just how much difference exists inside a forest where the distances reach 100km and over. The ordinary methods of analysis are ineffective as only samples of a few cm of wood are assessed in laboratories and are thus representative only of themselves.

With NIR (Near Infra-Red) technology every stave is controlled under infra-red light and its aromatic and structural features are analyzed online in order to have all the information as if it were a radiography.

With NIR we have been able to identify 4 commercial categories:

Structure: it identifies the structural feature, is wood characterized by high contents of tannin and ellagitannins. The wine acquires structure and body, the color settles.

Sweet: it identifies the sweet feature, is wood characterized by high contents of vanillin and furfural. The wine acquires hints of sweet aroma.

Spice: it identifies the spice feature, is wood characterized by high contents of lactone and eugenol. The wine acquires hints of spice.

Equilibrium: it identifies that there is no dominant character. The wine takes on a flavor which is a mixture of the ones mentioned above and the wood feels well-balanced. We have also been able to identify the markerfor the Erbacea feature, bitterness which if present in a large quantity is not eliminated even after many years of aging. This type of wood is therefore discarded and destined for other uses