Wine Presses

Central Inflating Wine Presses

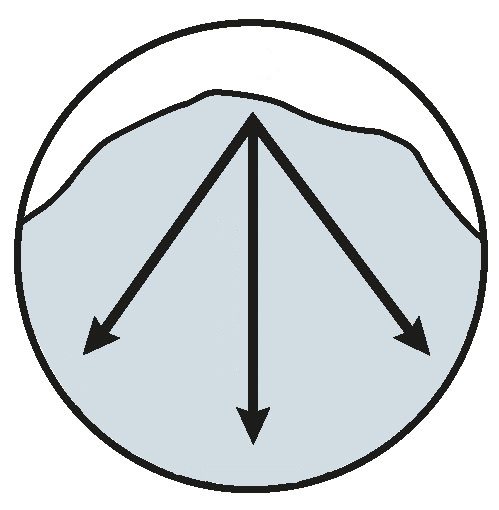

Central Inflating Membrane Presses have several advantages over traditional nylon bladder wine presses. By locating the wine presses membrane (which is over 1/4" thick) in the center of the press drum, the press is pressing with uniform pressure in 365 degrees. When the membrane is inflating the drum is always rotating so the grapes are the same thickness all around the outside of the drum. The outside of the press drum is the largest diameter of the drum. What this technology does is creates a much thinner cake vs having a bladder sewn in the side of a drum and pushing the grapes in one direction and creating a thick cake. The thinner the cake the easier it is to extract the juice. Thinner cakes require less pressure to achieve higher yields. Less pressure equals getting less of the heavy tannins in your must and wines. The heavy bitter tannins you don't want that are trapped in the grape skins that come out into your wine with heavy pressure.

Having a thin cake also makes it easier to extract the juice, as it is performed in almost half the time! Reducing pressing times, reduces your oxygen exposure and protects your whites from browning. The press also does not have to break the cake as many times as a traditional nylon wine presses does, so you end up with less lees in your wines. Most traditional nylon side inflating presses come in a closed drum because of this long oxygen exposure while being in the press for so long. Central inflating membrane presses even with a fully pierced drum have less oxygen exposure than closed drum traditional nylon bladder presses. The over 1/4" thick membrane is also very easy to clean as it sucks up tight to the central tie rods smoothly with no accordianing for bacteria to hide. The membranes are also designed to reach the entire circumference of the drum! This means they have no minimum grape loading capacities, you can press any size lot in a large press!

Benefits of Central Inflating Membrane vs Traditional Nylon Bladder Presses

- Higher Quality Yields

- Higher Yields per Ton

- Less Heavy Tannins

- Faster Pressing Cycles

- Less Oxidation

- Less Browning on Whites

- No Load Minimums

- Longer Bladder Lifespan

New Technology Central Membrane Wine Presses

Higher Yields at Much Lower Pressures

Higher Quality Yields

Less Heavy Tannins

Less Oxidation, Less Browning on Whites

No Load Minimums

Bladder can reach the entire Circumference of the Drum

Uniform Pressure throughout the Drum

10 to 20 year lifespan on the Membrane! (5/16" Thick)

Lower Energy Consumption

Ability to Press Crushed Apples and Deshelled Pomegranates

Old Technology Bladder Wine Presses

Lower Yields at Higher Pressures

Introduction of Heavy Tannins from the Skins Due to High Pressures

Longer Pressing Cycles

More Lees due to having the break the Thick Cake more times

More Oxidation, More Browning on White due to Longer Pressing Cycles

Bladder can reach the entire Circumference of the Drum

Minimum Load Capacities for Press use and Press Efficiency

Thin Nylon Bladder (1/16" Thick) easier to tear, needs to be replaced more often

Higher Energy Consumption

Cannot Press Crushed Apples or Deshelled Pomegranates

Please Feel Free to Contact Us for a Customized Quote

Winery

Winery Distillery

Distillery Brewery

Brewery Olive Oil

Olive Oil