Garbellotto

Garbellotto French Oak Wine Barrel 100L Medium Toast

$575.00 This item requires freight.

Stand is Included

Garbellotto French Wine Barrels

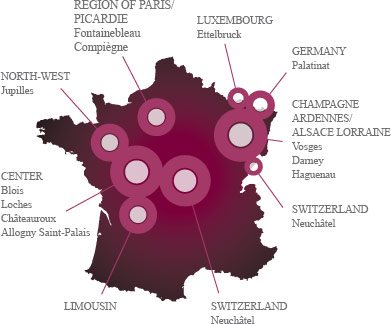

In order to provide more complete service, Garbellotto has realized a renewing of the barrel line, not only aesthetical: the hoops have been rationalized with circles narrower and thicker in order to have the same static seal, but increasing the surface area of free wood, and so the micro-oxygenation; the available range of wood and thickness has been expanded, having wood throughout all France, not only in the Central Massif, but also near Paris in Fontainebleau.

Bending of staves is always carried out using a direct flame and the exclusive DTS® method which allows the heat level of the flame to be digitally controlled, maintaining all wood at the same temperature without any changes to the aromas.

Thanks to the Digital Toasting System®, bending is followed by toasting, a process in which the temperature is also controlled precisely. Laser probes detect the interior temperature throughout the wood’s surface.

These probes are connected to a tablet which manages increases or reductions in temperature, so that if medium toasting requires 185°, then this temperature will be even across each square centimetre of the wood. This allows toasting to penetrate deep inside the wood, enhancing the release of aromas, which may even be pre-selected thanks to NIR® technology.

Toasting:

The following toasting options are available: light at 180°, medium at 185°, medium-plus at 190° and strong at 210°.

The final step is the finishing touch, consisting of interior and exterior planing followed by sand-papering, in order to make the surfaces truly magnificent to look at.

Range:

Oak Origin:

- France: Allier, Never, Fontainebleau, Limousin, Vosges;

- Slavonia

- American oak: Missouri, Pennsylvania.

Special wood selection:

We also offer special solutions of wood for particular purposes, as blend of different oak origins and also different varieties of wood (acacia, cherry, ash, chestnut, etc).

Grain:

We offer only high quality splitted wood with tight grain.

The medium grain is not used for our barrique and tonneaux.

French oak and french border forests oak

Accessories

Standard accessories:

- Silicon stopper for upper hole

For special needs we can provide the barrels with also other special accessories, on request we can apply the natural breathable paint that protects from excessive humidity.

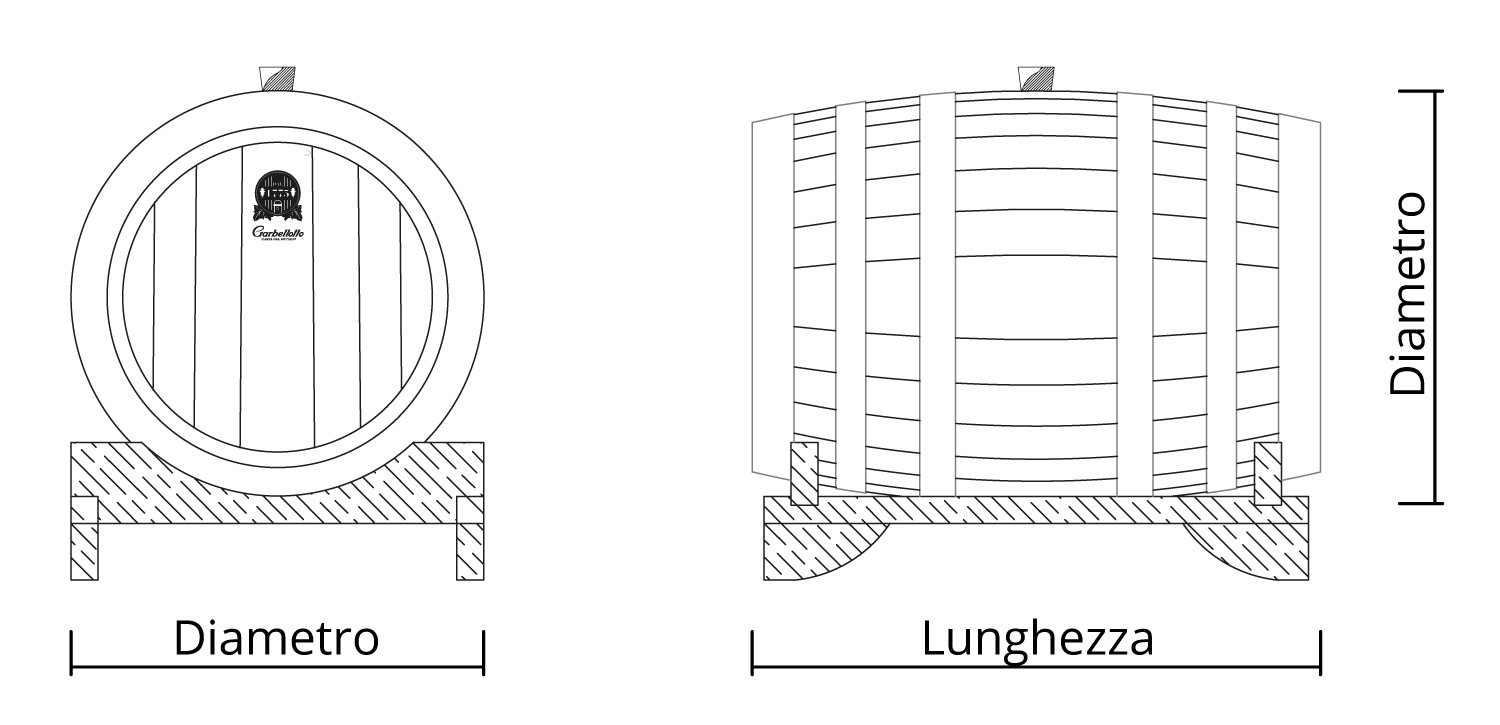

Size table

| CAPACITY | DIMENSIONS | |

| Staves | Diameter | |

| Liters | in cm | |

| 225 | 95 | 69 |

Patented NIR® only from Garbellotto!

The only barrels with flavor guaranteed (patented)

The growth of wood, like grapes and all natural products, depends on micro climatic variables such as the degree of humidity in the area, the composition of the earth as well as the exposure of the hill or plain. The selection criteria generally used are based only on the region and the experience of the producer. It cannot be said that wood originating from a specific region has a higher level of polyphenols than others grown in other regions, since the origins don’t make the difference, whereas the single stave does. If we think about the difference between the grapes produced in one vineyard and others produced at a distance of 5 km we can well understand just how much difference exists inside a forest where the distances reach 100km and over. The ordinary methods of analysis are ineffective as only samples of a few cm of wood are assessed in laboratories and are thus representative only of themselves.

With NIR (Near Infra-Red) technology every stave is controlled under infra-red light and its aromatic and structural features are analyzed online in order to have all the information as if it were a radiography.

With NIR we have been able to identify 4 commercial categories:

Structure: it identifies the structural feature, is wood characterized by high contents of tannin and ellagitannins. The wine acquires structure and body, the color settles.

Sweet: it identifies the sweet feature, is wood characterized by high contents of vanillin and furfural. The wine acquires hints of sweet aroma.

Spice: it identifies the spice feature, is wood characterized by high contents of lactone and eugenol. The wine acquires hints of spice.

Equilibrium: it identifies that there is no dominant character. The wine takes on a flavor which is a mixture of the ones mentioned above and the wood feels well-balanced. We have also been able to identify the markerfor the Erbacea feature, bitterness which if present in a large quantity is not eliminated even after many years of aging. This type of wood is therefore discarded and destined for other uses

DTS® - Digital Toasting System

The toasting is the process that enhances the flavors of the wood catalyzing those already present in the same and positively evolving them. Until now this process was realized on a brazier fed with pieces of oak where it was placed the barrel or cask. It is clear that the wood evolves these aromas according to toasting temperatures, which must be on the range of 170/180/200 degrees centigrade depending on whether you seek, more or less aromas of vanilla, licorice, chocolate, or tobacco smoke.

If the temperature and internal exposure of the staves is not homogeneous and controlled, the result are casks or barrels with aromas undefined. The staves taking less heat will develop bitter and negative aromas, the staves that take too much exposure can produce negative aromas of graphite. For this reason we created and patented the DTS® digital toasting, where a tablet, thanks to sensors, can handle the fire levels so that it is constant over the entire surface of the wood.

This not only guarantees but enhances the aromatic result of wood eliminating once and for all the “surprises” due to a toasting system not perfectly controlled. We offer:

170° Light Toast

175° Light/Medium Toast

180° Medium Toast

190° Medium Plus

200° Heavy Toast

Winery

Winery Distillery

Distillery Brewery

Brewery Olive Oil

Olive Oil

Share:

Share on Facebook Share on Twitter Share on Pinterest Tell a friend